Tooling<em>.</em>

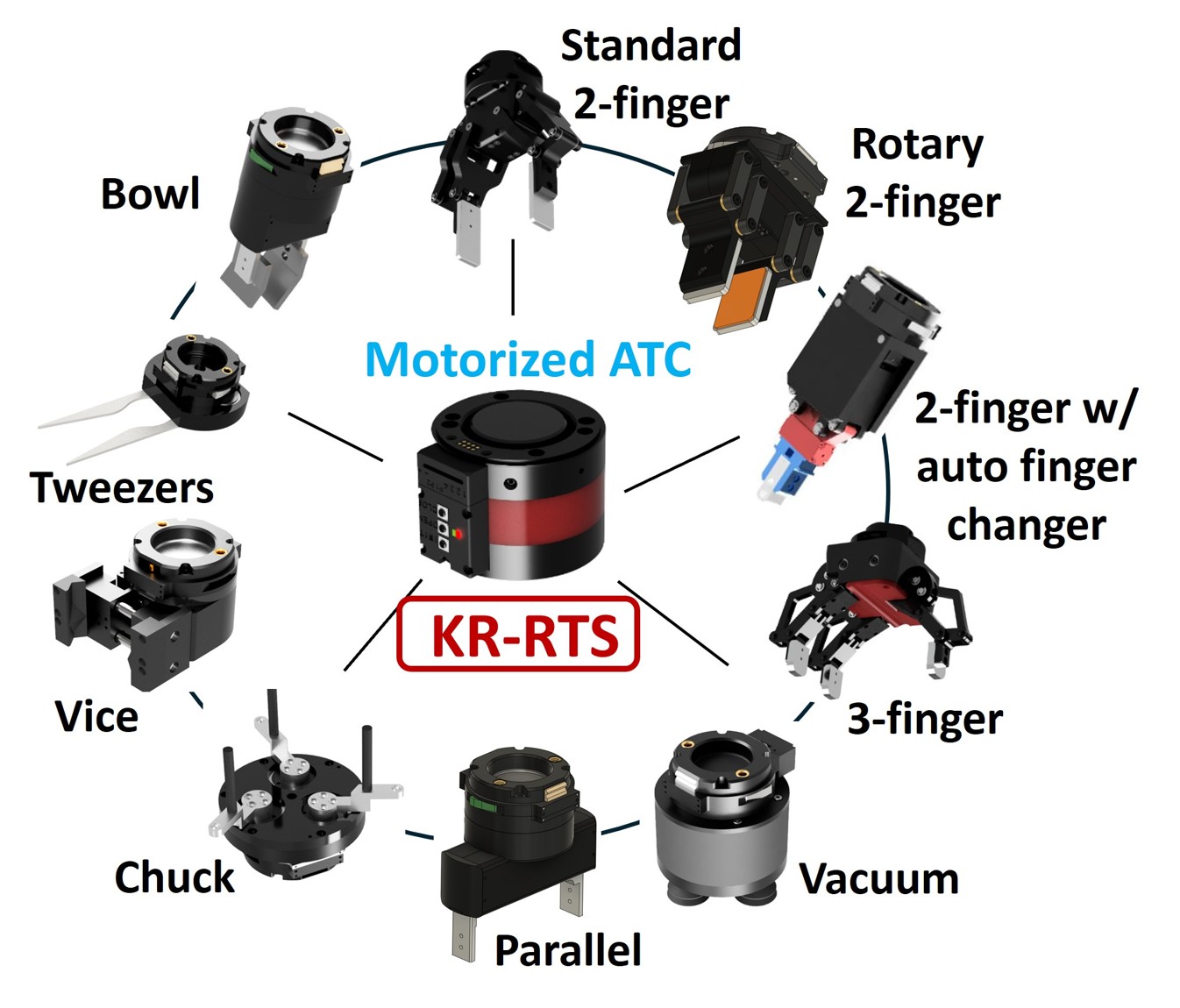

A new-concept robot tooling system consisting of a motorized automatic tool changer (MATC) and other various tools

Background

- Robot hands

Although capable of performing a wide variety of tasks, their high cost and low durability make them impractical for real-world use. - Tools (including grippers)

They offer low cost and high durability but can only handle simple tasks. - Combination of the advantages of both approaches

By automatically changing various tools, a robot achieves the versatility and dexterity of a robotic hand while maintaining durability and simplicity. - Problems

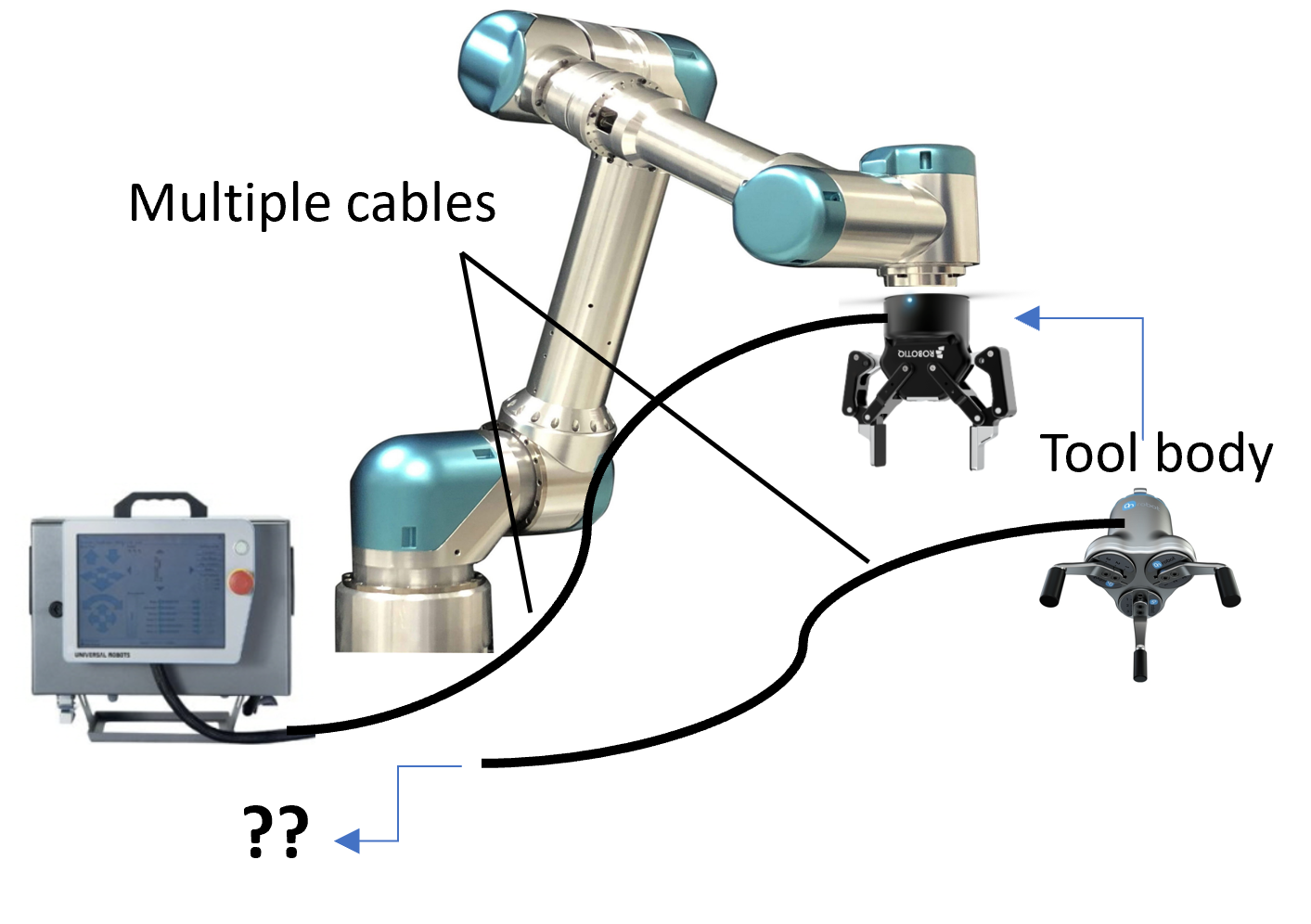

Since the tool’s power and communication cables must also be changed together with the tool, the tool must be changed manually before operation.

KR-RTS is

a novel tooling system that enables automatic tool and finger changes during operation.

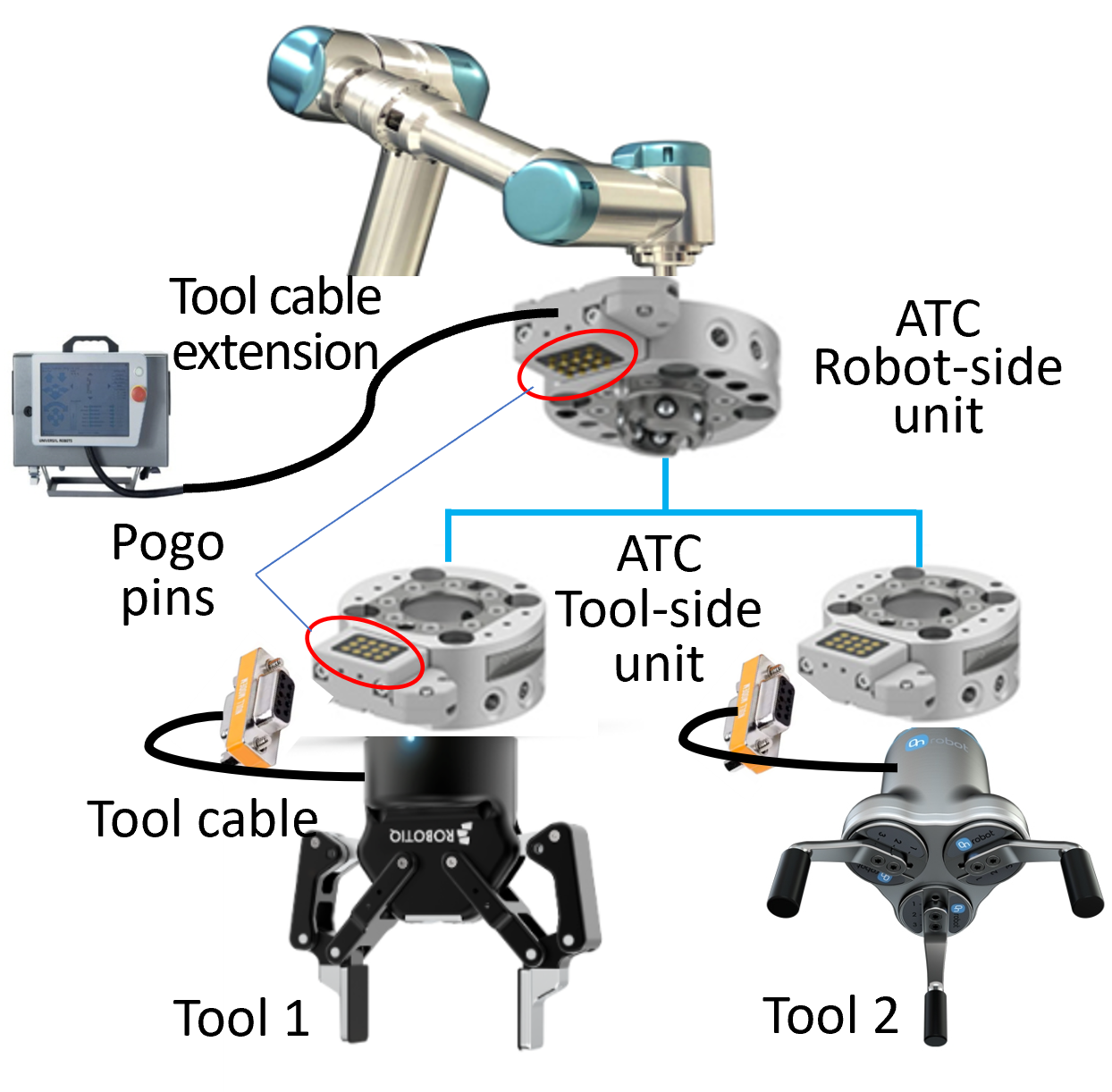

Conventional ATC-based Tool Change

Tool Change Based on ATC (Automatic Tool Changer)

- ATC robot-side unit: Mounted on the robot flange, with the tool cable extension connected to pogo pins.

- ATC tool-side unit: Mounted on the top of the tool, with the tool cable connected to the pogo pins.

- When the robot and the tool are coupled, power and signals are transmitted between the robot and the tool through the pogo pins.

- Since ATCs typically operate using pneumatic locking mechanisms, an external air supply is required. As a result, their use is limited in systems such as AMRs, where pneumatic supply is difficult to provide.

Features

- Existing commercial tools can be used without modification; however, connecting the tool cable and tool cable extension to the pogo pins is time-consuming and cumbersome.

- Since each tool requires its own dedicated drive unit (motor + controller), the cost increases significantly as the number of tools increases.

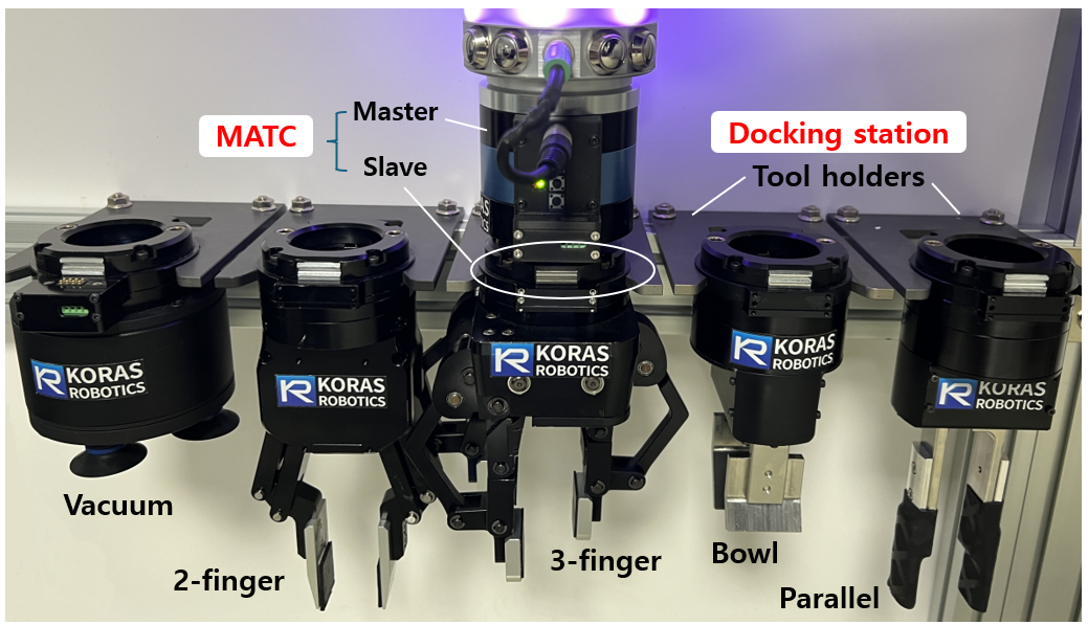

Novel MATC-based Automatic Tool Change

Motorized Automatic Tool Changer (MATC)

- MATC robot-side unit : Mounted on the robot flange. The built-in shared drive unit (motor + controller) is connected to the robot controller or a higher-level controller via a tool cable.

- MATC tool-side unit : Mounted on the top of the tool that is composed of a purely mechanical structure without any built-in actuators.

- Regardless of whether a tool is coupled or decoupled, the drive unit remains permanently connected to the robot.

- MATC operates using a latch-based locking mechanism and requires no pneumatic supply.

Since all operations are performed solely by robot motion, MATC can be conveniently used in AMRs and other systems where pneumatics are difficult to provide.

(Motor, Controller & Cable)

- Since all tools share a single drive unit embedded in the MATC robot-side unit, the robot remains constantly connected via a single tool cable (power and communication).

- Through control of the shared drive unit, motor power with task-specific torque and speed characteristics is delivered from the MATC robot-side unit to the tool-side unit, according to the characteristics and requirements of each tool.

MATC-Compatible Mechanical Tools

- Each tool is composed of a purely mechanical structure without any actuators. MATC-compatible tools are equipped with an MATC tool-side unit on the top, which enables coupling and decoupling with the robot-side unit.

- Each tool includes a power input interface capable of receiving motor power transmitted from the MATC robot-side unit.

Power Transmission

- Instead of mechanical gears, which can cause various contact-related issues, rotational power is transmitted between the MATC robot-side unit and the tool-side unit via magnetic coupling.

- Because there is no mechanical contact in the power transmission interface, smooth and reliable tool exchange is possible even under frequent coupling and decoupling.

Key differences from conventional tooling systems

| Conventional Tooling Systems | KR-RTS | |

|---|---|---|

| Custom tools | Custom tools are NOT available. | Custom tools are available. |

| ATC locking | The ATC can be locked pneumatically or electrically. | The ATC’s latch is locked without the need for external power. |

| ATC functions | The ATC is designed solely for its own locking function. | In addition to its locking function, the motorized ATC (MATC) can deliver rotational power to each tool through its built-in drive unit. |

| Tool drive unit | Each tool requires its own drive unit for operation. | Each tool does NOT require its own drive unit for operation. |

| Tool lineup | The types of tools available are limited. | More than 15 types of tools are available, enabling the handling of nearly any object. |

| Compliance | Compliance is not provided in the gripper. | Control-based compliance is provided, allowing the handling of soft objects. |

| Finger changing | Manual changing before operation. | Automatic change during operation. |

| Manufacturers of ATC & tools | Since the ATC and tool manufacturers differ, it is difficult to build a consistent tooling system. | Since the ATC and tool manufacturers are the same, it is easier to establish a consistent tooling system. |

| AI-based tooling SW | Not available. | Offers automatic selection of an optimal tool type and estimation of tool pose. |

Tool Lineup of KR-RTS

How to Use

Method 1) MATC + MATC-compatible tools

The MATC robot-side unit is mounted to the robot flange, while the tool-side unit is mounted to the tool. Tools are placed on the tool holders of the tool change station. When the robot moves to couple the robot-side unit to the tool-side unit of the MATC, the tool is automatically attached to the robot. Controlled motor torque and speed generated by the MATC’s drive unit are transmitted to the tool to ensure proper operation. The MATC-compatible tool does not contain its own drive unit but instead incorporates a tool-side unit that connects to the MATC.

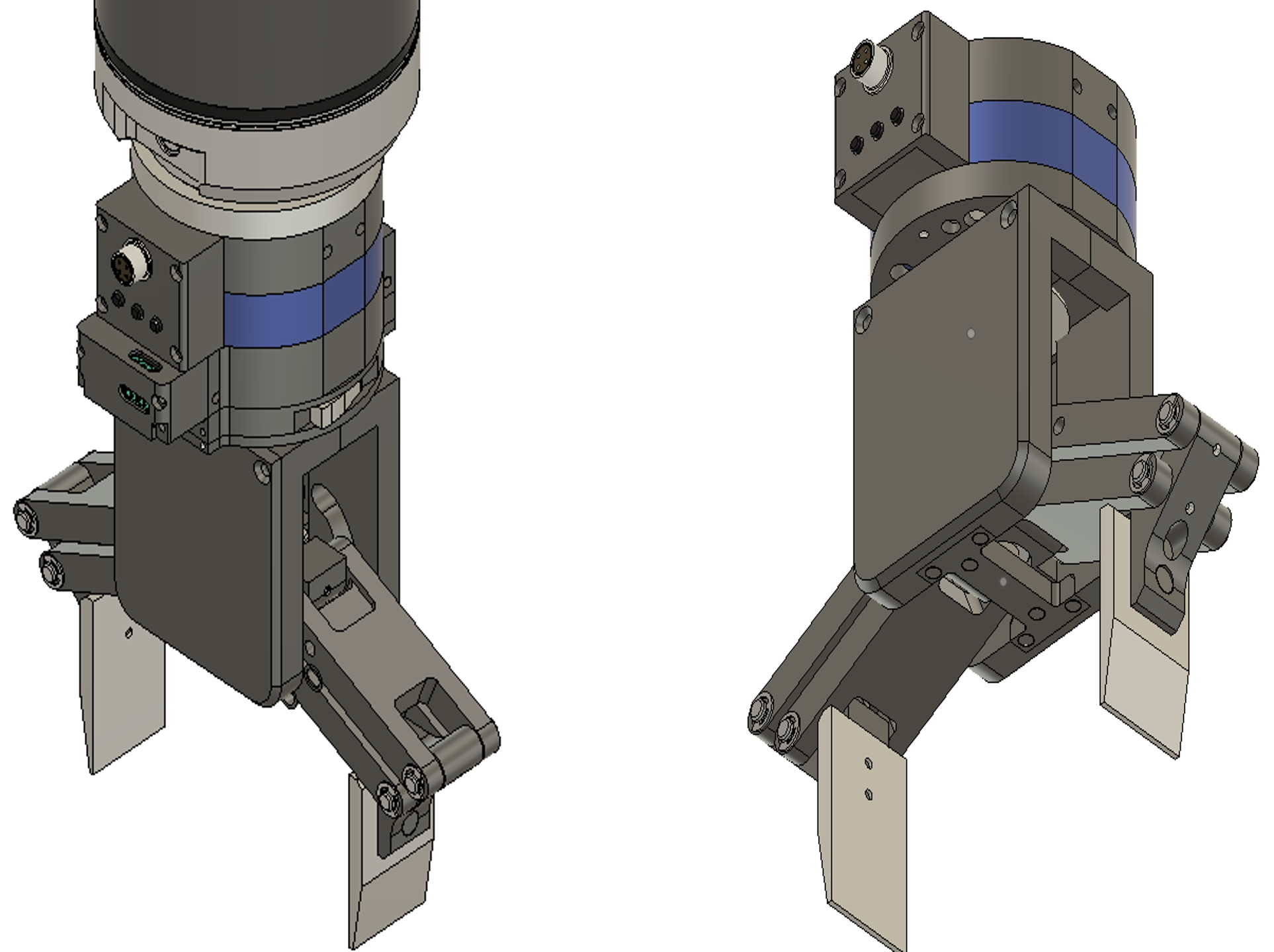

Method 2) Integrated tools

The tool has a built-in motor and controller, allowing it to operate without the use of MATC. This is the approach adopted by most commercial grippers.

<MATC-compatible 2-finger gripper (left) and integrated 2-finger gripper (right)>

Application areas

Products

- Automatic Tool Changer (ATC)

- Motorized Automatic Tool Changer (MATC)

- Standard 2-Finger Gripper (4 kg payload)

- 2-Finger Gripper with Interchangeable Fingers (4 kg payload))

- Rotary 2-Finger Gripper (3 kg payload)

- Rotary 2-Finger Gripper (10 kg payload)

- Rotary 2-Finger Gripper (20 kg payload)

- Standard 3-Finger Gripper (5 kg payload)

- Vacuum Gripper (4 kg payload)

- Parallel Gripper (3 kg payload)

- Compliant Parallel Gripper (3 kg payload)

- Offset-Tolerant Parallel Gripper (2 kg payload)

- Parallel Gripper (11/15 kg payload)

- Parallel Gripper (30 kg payload)

- Chuck Gripper (3 kg payload)

- Chuck Gripper (15 kg payload)

- Radial Gripper (12 kg payload)

- Vice Gripper (5 kg payload)

- Bowl Gripper (3 kg payload)

- Tweezers Gripper

- AI-based Tooling

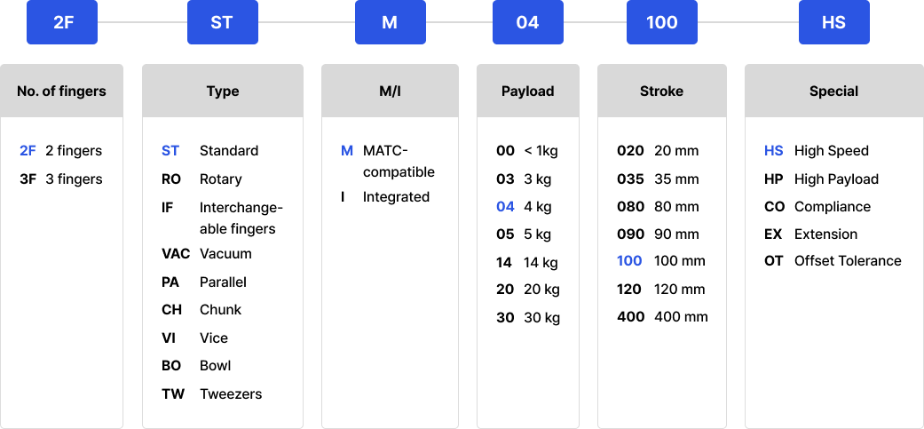

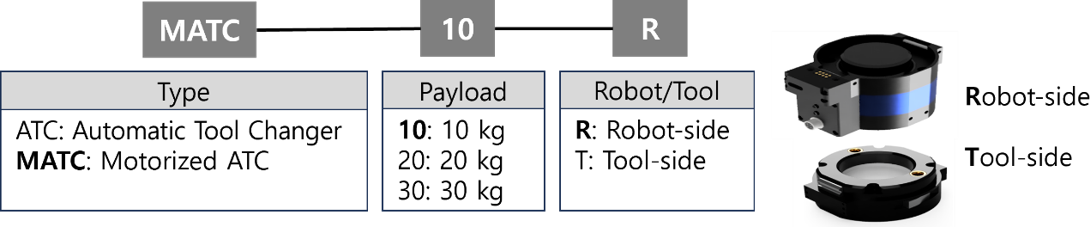

Model naming system

- Tool changers

- Grippers